By field welding or bolting. Hardness finish and conformity of race and rolling elements determine load capacity which varies as the fourth power of the.

The Minirail series is a family of robust two-row miniature guideways made from stainless steel.

. Good strength and load tolerance define mechanical attributes. The load endured by a linear slide bearing is a combination of variable forces vibrations impacts occasional loads etc. This book is primarily about bearingless machines where the magnetic levitation of the rotor is provided from within the main stator bore in addition to torque production if motoring or electrical power production if generating.

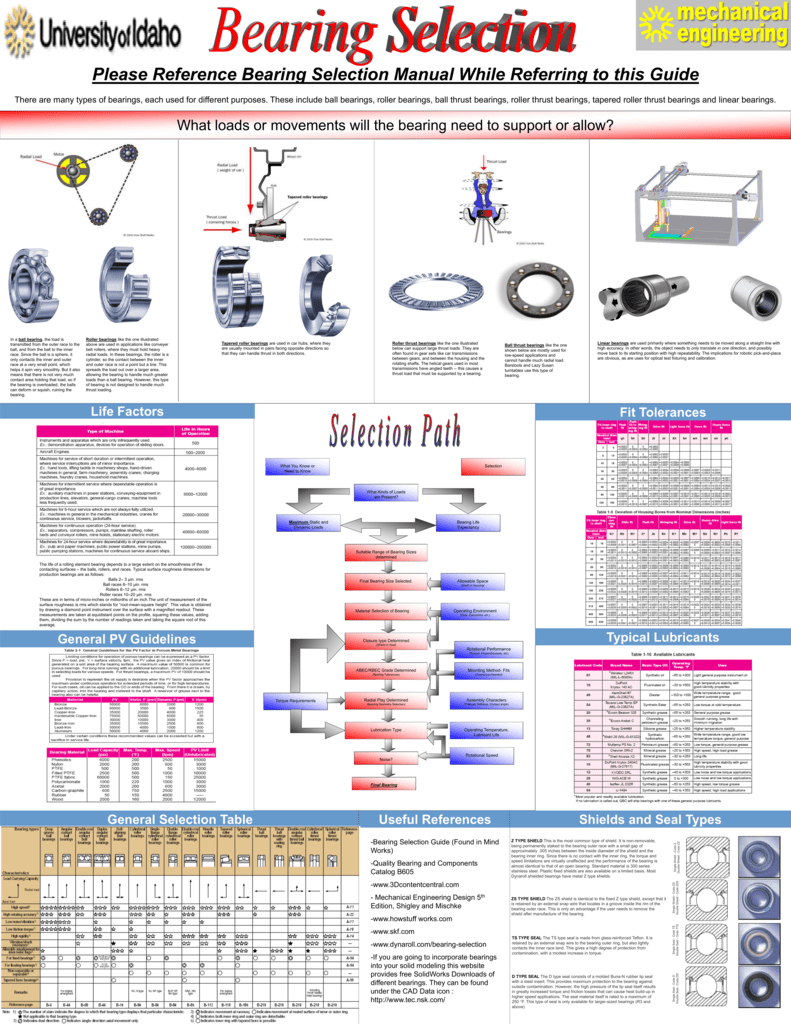

Ball bearings are used primarily to support rotating shafts in mechanical equipment. In the early stages of the application analysis and design process bearing selection is initially made using various assumptions and as the process progresses additional input is included to fine tune results. Moving parts of machines must be located and supported invariably by the appropriate bearing design and selection.

Delrin separators can typically only withstand temperatures less than 180ºF. A shaft and bushing bearing is known as a journal bearing. They can be found in everything from personal computers to passenger cars.

Bearings capable of supporting a radial load are often called journal or sleeve bearings while those carrying an axial load are termed thrust bearings. They are of simple design and can be precision made in mass production quantities. The fluid lubricant forms a film between the.

World there are several standards for through hardened bearing. A Guide to Form Function and. Bearings are the machine elements that permit relative motion between two components and transmission of load from one to the other.

Craig 25 In machine tool structure if one is to minimize bending the length of the structure should be no. The bearings are normally vulcanized to a top plate or sole plate. Factor for Load Type.

Bearing self study guide Expanding your knowledge of bearings and related components. Magnetic Bearings and Bearingless Drives. Bearings can be classified as providing sliding or rolling contact.

Ball bearings are used primarily to support rotating shafts in mechanical equipment. Is added to bearing ID. Mechanical Engineering May 25 2022.

Table of contents Introduction. C 3 added to the bearing ID. Predicted values meet actual design requirements.

Priate bearing type that can be per-formed as intended is a daunting engi-neering task. Allows for this close-in. This document makes the following design and detailing assumptions for elastomeric bearings.

Linear-Bearing Design Considerations. As shown in Table 2 if the center of an individual load is specified at a relative distance from the guideway system or bearing centers then the total mass has a CG. Masonry plates and anchor rods are not normally required.

Relative motion leads to loss of power due to friction and deterioration of contacting surfaces due to wear. In addition to the single row design there also are double row angular contact and ball thrust bearings. Bearings capable of supporting a radial load are often called journal or sleeve bearings while those carrying an axial load are termed thrust.

An advanced ball-retainer design simplifies assembly and. C3 Press Fit Allowance Bearing Wall Thickness in 18 316 14 38 12 34 1 and up C 4012 017 021 026 030 032 033. Elastic behavior and creep resistance are two basic considerations for plastic bearings.

It may amount to picking a bearing from a catalog on the basis of PV factor or may require a sophisticated analysis of lubricant flow. We use the load type factor fw. Bearings are needed whenever one part of a machine slides against another.

Every mechanical system involves relative motion between different machine elements. The design and mechanism of bearings having low friction material cages is describedthe dry lubricating materials considered are ptfe-compositestypical operating conditions are. A Practical Guide J.

The design data. Detailed Mechanical Design. Mechanical Design Guidelines For Bearings Mariners Repository Bearings Design Guidelines - magnitude and direction of the thrust load if any.

The design and mechanism of bearings having low friction material cages is describedthe dry lubricating materials considered are ptfe-compositestypical operating conditions are. Distance to the guide rails. Bearings are to effectively resist moments applied to the shaft.

Information and recommendations on sealing solutions are provided as well. Mechanical Design Fundamentals K. The minirail guideways come in 7 9 12.

2 Chapter 1 History of bearings. Plain bearing design may be simple or complex. The bearing bears directly on the concrete.

The bearings are attached to the girder. Design of bearing arrangements. This section provides most of the information that is required when designing a spherical plain bearing arrangement for maximum bearing performance.

They can support heavy loads over a wide speed range and do it virtually friction free. When bearing is pressed into housing. 7 Figure 21 d.

SKF can support you throughout this process with our engineering software tools diagram 1 ranging from easy-to-use online tools. The characteristics and uses of each type will. Basic static load Basic static load Cor is given in the bearings catalogues for every size and it is taken in consideration when the bearing is stationary has slow oscillations low speed n.

A sliding bearing typically uses a lubricant to reduce friction between the sliding surfaces. Changes in continuous or maximum service. When NYCAST materials are pressed into a housing the bearing experiences close-in.

Jigs Vs Fixture Jigs Mechanical Design Fixtures

Mechanical Design Guidelines For Bearings

How To Pinpoint The Best Plain Bearing Machine Design

Mechanical Design An Overview Sciencedirect Topics

Lean Principles Lean Manufacturing Principles Mechanical Design

0 comments

Post a Comment